RADAR NDT

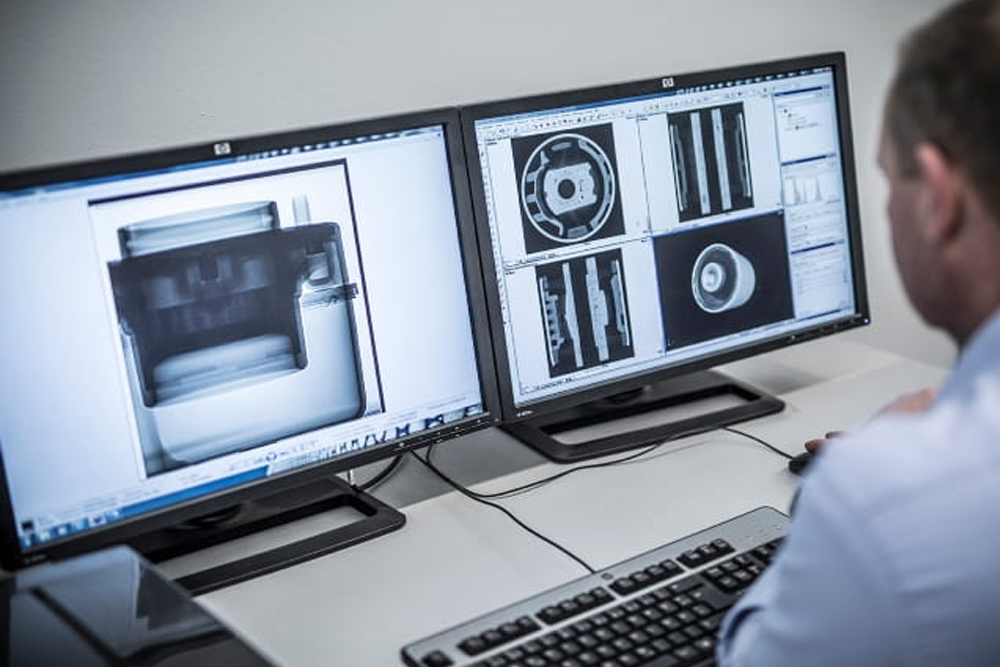

Radiography (X-ray) is one of the most important, versatile, and widely accepted of all the nondestructive examination methods. Whatever the standard of quality, all welds should be inspected. X-rays images (RT Films) are useful in detecting Interior macroscopic flaws – cracks, porosity, blowholes, non-metallic inclusions, incomplete root penetration, undercutting, icicles, and burn through. Currently, the RT images are manually interpreted by highly skilled radiologists, either using an illuminator or digitized films viewed on a computer screen. The ability of an individual to detect discontinuities in radiography is also affected by the lighting condition in the place of viewing and the experience level for recognizing various features in the image. This is a time-consuming and repetitive task (considering the 100s of images per job), which when compounded by limitations like, image quality and human fatigue, can cause errors in defect detection.

RADAR NDT is a web-based tool for identification, marking, and measuring defects in welded joints, from digitized images of the welds. RADAR NDT uses Deep Learning and Artificial Intelligence to quickly process the image, identify the defects, classify the images as defective or not. In images with defects, RADAR NDT marks and measure each of the defects individually making it easier for the radiologist to draw acceptance conclusions.

RADAR NDT is capable of accepting images both from conventional X-Ray (digitized RT Films) and Digital X-Ray films, Ultrasound, and other modalities.

Applications

Power Plants

Railways

Oil & Gas